Aaah vehicles, the joy they bring when they're working and the test they become when they aren't!!

Whilst enjoying a second attempt at the Ulverston to Holy Island Coast to Coast route this weekend, my bike decided to have a hissy fit and die in the middle of nowhere! It appears I'm not meant to finish this route...

I'd had a bit of a warning as the cam chain went rattly part way through the morning, but as the riding was pretty good and the many river crossings were going pretty well, I was being lazy and just hoping it was fine until we stopped that evening and I would look at it then, however the engine had other ideas it appears!

So with the much appreciated help of three friends, the bike returned to the van and back to my house. I commiserated with Lucy and a bottle of red wine, before sleeping and dreaming of the many possibilities of both damage and expense I would be facing!

Sunday morning dawned, I stripped the bike and lifted the engine out, so below is how I did it. It is much easier than on earlier bikes although I think the injection system is something to really take care of on re-assembly.

Setting up;

1. Strip the bike of fuel tank and plastics, including the frame protector plastics

2. Disconnect the battery

3. Take out the air filter, block up the inlet

4. Jet wash the bike thoroughly including the electric cables above the engine and in all the little places dirt hides

5. Wipe clean the top of the engine and remove any last bits of dirt from the cables.

6. Let it dry

7. Drain the coolant

8. Drain the oil

Removing the Engine;

1. Pop the bike on a stand with the back wheel hanging free

2. Remove the coolant hoses from the engine

3. Loosen the injection system clips and break the seal of the hoses

4. Unplug the stator lead at the two connectors, one black, one blue.

5. Remove the air box hose from the top of the cam cover casing

6. Remove the spark plug cap

7. Remove the bottom rear shock bolt

8. Remove the rear brake spring

9. Remove the cable attached to the starter

10. If you have a chain guard, remove this

11. Loosen the chain and remove the front sprocket

12. Loosen and lift out the clutch slave cylinder, (lay it over the frame)

13. Remove the swing arm bolt and ease the swing arm away from the engine.

14. Remove the retaining springs from the front of the exhaust & the silencer

15. Remove the silencer and the front header pipe from the bike

16. Unclip the sensor on the left side of the engine

17. Loosen the engine mounting bolts at the top of the engine (3 x 13mm nut & bolts)

18. Remove the two engine mounting bolts (2 x 13mm with captured nuts)

19. Ease the engine out to the left and pop it on a stand

Now the fun begins!

Breaking the engine apart is easy, these KTM bikes are designed to be field maintained whilst racing etc for the most part. There are a few jobs on them that requires specialist tools but for the most part you can just find what's broken, pull it out and replace it. Simples!!

What I needed to do required the following;

1. Undo the 3 x 10mm bolts holding the black engine cover on

2. Lift the cover away with the seal and lay it carefully to one side.

3. Inspect the cams and cam chain.

The cam chain wasn't sat right on the cam cogs, the cams themselves wouldn't move at all, so the valves looked like they weren't happy. To get to these, you have to remove the next layer of engine casing. (Make sure you write down which cam comes from where and what size shim is in there!).

This requires the following;

1. Loosen off the 8 x 10mm bolts holding the camshaft bridge.

2. Lift the bridge off gently, easing the oil cartridge out carefully.

3. Lift out the cams and place them carefully to one side. (I checked them for scoring or wear marks)

4. Locate and release the 2 x 13mm nuts inside the engine casing

5. Loosen the two external 13mm bolts released. (These are tight, so use a long bar and a good fitting socket),

6. Then there is an 8mm nut on the other side of the engine

7. Using a mallet, gently tap around the engine casing until you can see the casing lift slightly, then ease it off the engine.

As this bike has done 400+ hours, I thought I might as well look at the piston as well, it's fine to be honest, it is coming up due for a replacement so whilst I'm doing this job anyway, it'll get replaced and I'll send the barrel to Langcourts again for a replacement Nicosil coating and honing. In the old manuals, they told you the size of the piston and the bore on the cylinder, in the current one, however there are no sizes, so I'll have to do a bit of research to find out.

This has all the KTM 350 2012 specs.

To remove the valves however is one of those jobs that needs a special set of tools, namely a valve compressor plus a set of valve grinders and some grinding paste. I don't have these, so will go see a friend who does and deal with them from there. once I find out what needs replacing I'll order the parts but one thing I have learnt from experience is to replace all of the seals and the gaskets anyway. Don't skimp on this, it will come back to bite you.

The workshop manual for this bike is HERE

The KTM manuals page is HERE

05/08/2018 - All the parts have arrived!

Now I have lots of expensive shiny things, I started to rebuild the engine. I also bought a valve removal tool and a chain splitter small enough to break the cam chain as they come as a sealed circle. You need something that goes to 2mm diameter for this and I only found one choice here in the UK. Remember to coat everything in fresh engine oil as you rebuild or buy the specific sticky oil which doesn't drain off as you're rebuilding things.

Changing the Cam Chain

Cam chains these days are pretty reliable, but they do wear, and Geoff, a mate of mine who helped me rebuild my old 400 (who is also a bloody good race mechanic). They wear the same as the main drive chain, ie the rollers and plates wear away, which creates bigger gaps and makes the chain sloppy. A good way to check this is to measure the chain from pin to pin and look up the tolerance for your bike, or just change it anyway as it's good practice!

Pop a rag into the engine block to stop debris dropping into the engine, then using the 2.2mm pin drive on the chain tool, you push out the pin on the old cam chain, do not remove it all the way. Split the new chain in the same way and attach one end to the old chain, then pull it through the bottom end, split the old chain from the new and re-install the pin to close up the new chain. Job done.

Installing the Piston.

Inserting the new piston into the newly coated middle section of the engine block is not easy. Pop the gasket on first, the if you have the KTM tool, it must be easier, but I didn't, so I first attached the piston and tried to lower the casing onto it, but it catches on the piston rings, so I too it back off and inserted the piston (on the workbench) partway just to hold the rings in place. Be very careful not to damage the bottom oil ring as it is made up of two parts, a long spring and the outer race, they are joined but very fragile, if you bend or damage it you have to get a new one and try again. One I had the piston mounted, I then popped it onto the crankshaft. This is a delicate job, so have some patience and get the locking ring on the gudgeon pin in place, I needing a flat bladed screw driver and lots of patience. (Remember to pop a rag into the engine hole below where you're working or when you drop the ring it'll be a much longer job!! ).

So the stages are;

1. Pop gasket in place

2. Oil the cylinder face and piston parts

3. Insert gudgeon pin partway into piston

4. Insert piston into cylinder just to hold piston rings in place.

5. Put piston on to crankshaft with the casing attached, ease the cam chain and cam chain guides through the new casing to get this into place.

6. Drop into place making sure it all fits neatly.

7. Pump the piston to make sure it moves nicely.

Building the Head

I spent a fair bit of time on rebuilding the cylinder head, mainly so I could learn about it and also as it is expensive if you get it wrong!! A full valve kit is around £350, so for us mere mortals in the money world, you only ever replace what you need to. In my case I checked all the valves and could only find one that osculated very slightly, so I took all four valves to WM Moto in Carlisle for a second opinion. They agreed and so I ordered the replacement intake valve from them and the cam chain adjuster, which is what had started all this rebuild!

Installing the Valves

Once the rest of the parts arrived I rebuilt the cylinder head, installing the valves into their guides and really taking my time. Each valve goes into place, then I used the valve tool and paste to lap them into place and make sure the fit is tight with no burrs or visible holes. (Here is a YouTube film of a car engine being done). I could have saved myself this job if I'd recorded which valve came from where, but as I had to do it for the new valve, I did it for all of them to be sure. Check the servicing manual for the exact specs on all the parts to this.

Once happy with that part, I turned the head over and mounted it into a vice, installed the valve springs and the collets with the valve compressor tool. For this you need a fine set of tweezers and a screwdriver with a magnetic end, as you will drop the collets and they will drop in sideways etc!!!

Once this lot was in place, bolted down and all torqued up then it was time to play with the cams. Head bolts are 50nm, the little bolt on the side of the engine is 25nm.

Installing the Cams

Mounting the cams is another one of those jobs, it's easy and can be quick, but make sure you get the timing set up correctly before you move on. In the service manual this part is done in two stages, 1. setting the timing, 2. installing the shims and setting the gap correctly. The service manual has a load of checks in it for all of these parts with the specs etc, it's a good idea to look at it.

Check the cams over for any wear and damage, for my bike, there is very little, but some things to look at specifically are chips of marks on the cam faces, damaged teeth, check the spring on the exhaust cam that releases the counter balance weight and the oil feeder on the intake cam. Also check the cam followers and the bars they sit on for wear. Install the intake cam first and work back to front.

Once you're happy everything is good, install the cam chain followers into the holes and seal up the external caps, (just check the o ring on these for damage). Pop the intake cam in place, then mount the chain over it and ease the exhaust cam under the chain and into its slots.

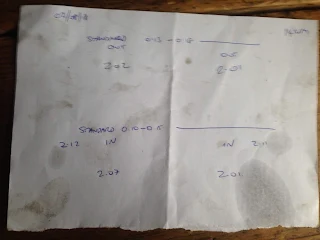

Once they're in place, mount the bridge, chain tensioner and tighten down. In the pic above is where to find the timing marks on the cams, (KTM has a specific tool for this to make sure it's correct as it affects a lot of things, so if you're unsure get a second opinion!). Once this bit is good, then demount the whole lot and look at installing the shims.

I measured these at least four times to make sure I was happy with it, each time you change something you have to rebuild the lot including using the torque settings for the bridge, but if it's wrong, you'll have to do it again anyway, so take your time and get it right first time. (Tolerances are in the manual but interestingly there is no starting size listed, so it may be worth asking your local KTM dealer if they know these).

Once this is all built, then check the timing again and torque down the bridge for the final time. Pump the piston a few times and check the timing again, then pop the spark plug cover in place and mount the black engine casing with it's three bolts.

Remount the engine and reverse the initial process at the top of this post. When you're all done, say a little mantra, 'it will work, it will work' and hit the starter button. This will either make you smile or cry!!

Whilst enjoying a second attempt at the Ulverston to Holy Island Coast to Coast route this weekend, my bike decided to have a hissy fit and die in the middle of nowhere! It appears I'm not meant to finish this route...

I'd had a bit of a warning as the cam chain went rattly part way through the morning, but as the riding was pretty good and the many river crossings were going pretty well, I was being lazy and just hoping it was fine until we stopped that evening and I would look at it then, however the engine had other ideas it appears!

So with the much appreciated help of three friends, the bike returned to the van and back to my house. I commiserated with Lucy and a bottle of red wine, before sleeping and dreaming of the many possibilities of both damage and expense I would be facing!

Sunday morning dawned, I stripped the bike and lifted the engine out, so below is how I did it. It is much easier than on earlier bikes although I think the injection system is something to really take care of on re-assembly.

Setting up;

1. Strip the bike of fuel tank and plastics, including the frame protector plastics

2. Disconnect the battery

3. Take out the air filter, block up the inlet

4. Jet wash the bike thoroughly including the electric cables above the engine and in all the little places dirt hides

5. Wipe clean the top of the engine and remove any last bits of dirt from the cables.

6. Let it dry

7. Drain the coolant

8. Drain the oil

Removing the Engine;

1. Pop the bike on a stand with the back wheel hanging free

2. Remove the coolant hoses from the engine

3. Loosen the injection system clips and break the seal of the hoses

4. Unplug the stator lead at the two connectors, one black, one blue.

5. Remove the air box hose from the top of the cam cover casing

6. Remove the spark plug cap

7. Remove the bottom rear shock bolt

8. Remove the rear brake spring

9. Remove the cable attached to the starter

10. If you have a chain guard, remove this

11. Loosen the chain and remove the front sprocket

12. Loosen and lift out the clutch slave cylinder, (lay it over the frame)

13. Remove the swing arm bolt and ease the swing arm away from the engine.

14. Remove the retaining springs from the front of the exhaust & the silencer

15. Remove the silencer and the front header pipe from the bike

16. Unclip the sensor on the left side of the engine

17. Loosen the engine mounting bolts at the top of the engine (3 x 13mm nut & bolts)

18. Remove the two engine mounting bolts (2 x 13mm with captured nuts)

19. Ease the engine out to the left and pop it on a stand

Now the fun begins!

Breaking the engine apart is easy, these KTM bikes are designed to be field maintained whilst racing etc for the most part. There are a few jobs on them that requires specialist tools but for the most part you can just find what's broken, pull it out and replace it. Simples!!

What I needed to do required the following;

1. Undo the 3 x 10mm bolts holding the black engine cover on

2. Lift the cover away with the seal and lay it carefully to one side.

3. Inspect the cams and cam chain.

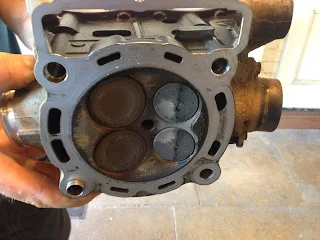

|

| Removed cylinder head |

This requires the following;

1. Loosen off the 8 x 10mm bolts holding the camshaft bridge.

2. Lift the bridge off gently, easing the oil cartridge out carefully.

3. Lift out the cams and place them carefully to one side. (I checked them for scoring or wear marks)

4. Locate and release the 2 x 13mm nuts inside the engine casing

5. Loosen the two external 13mm bolts released. (These are tight, so use a long bar and a good fitting socket),

6. Then there is an 8mm nut on the other side of the engine

7. Using a mallet, gently tap around the engine casing until you can see the casing lift slightly, then ease it off the engine.

As this bike has done 400+ hours, I thought I might as well look at the piston as well, it's fine to be honest, it is coming up due for a replacement so whilst I'm doing this job anyway, it'll get replaced and I'll send the barrel to Langcourts again for a replacement Nicosil coating and honing. In the old manuals, they told you the size of the piston and the bore on the cylinder, in the current one, however there are no sizes, so I'll have to do a bit of research to find out.

|

| Plenty of burnt fuel on here! |

|

| Not too much wear for 400+ hours |

This has all the KTM 350 2012 specs.

To remove the valves however is one of those jobs that needs a special set of tools, namely a valve compressor plus a set of valve grinders and some grinding paste. I don't have these, so will go see a friend who does and deal with them from there. once I find out what needs replacing I'll order the parts but one thing I have learnt from experience is to replace all of the seals and the gaskets anyway. Don't skimp on this, it will come back to bite you.

The workshop manual for this bike is HERE

The KTM manuals page is HERE

05/08/2018 - All the parts have arrived!

|

| Parts from Eurotek in Ripon |

|

| Ebay to the rescue again! |

Changing the Cam Chain

Cam chains these days are pretty reliable, but they do wear, and Geoff, a mate of mine who helped me rebuild my old 400 (who is also a bloody good race mechanic). They wear the same as the main drive chain, ie the rollers and plates wear away, which creates bigger gaps and makes the chain sloppy. A good way to check this is to measure the chain from pin to pin and look up the tolerance for your bike, or just change it anyway as it's good practice!

|

| The length of 8 pins on the old chain |

Installing the Piston.

Inserting the new piston into the newly coated middle section of the engine block is not easy. Pop the gasket on first, the if you have the KTM tool, it must be easier, but I didn't, so I first attached the piston and tried to lower the casing onto it, but it catches on the piston rings, so I too it back off and inserted the piston (on the workbench) partway just to hold the rings in place. Be very careful not to damage the bottom oil ring as it is made up of two parts, a long spring and the outer race, they are joined but very fragile, if you bend or damage it you have to get a new one and try again. One I had the piston mounted, I then popped it onto the crankshaft. This is a delicate job, so have some patience and get the locking ring on the gudgeon pin in place, I needing a flat bladed screw driver and lots of patience. (Remember to pop a rag into the engine hole below where you're working or when you drop the ring it'll be a much longer job!! ).

|

| Old (after some cleaning) and the new piston |

|

| New piston and barrel in place |

1. Pop gasket in place

2. Oil the cylinder face and piston parts

3. Insert gudgeon pin partway into piston

4. Insert piston into cylinder just to hold piston rings in place.

5. Put piston on to crankshaft with the casing attached, ease the cam chain and cam chain guides through the new casing to get this into place.

6. Drop into place making sure it all fits neatly.

7. Pump the piston to make sure it moves nicely.

Building the Head

I spent a fair bit of time on rebuilding the cylinder head, mainly so I could learn about it and also as it is expensive if you get it wrong!! A full valve kit is around £350, so for us mere mortals in the money world, you only ever replace what you need to. In my case I checked all the valves and could only find one that osculated very slightly, so I took all four valves to WM Moto in Carlisle for a second opinion. They agreed and so I ordered the replacement intake valve from them and the cam chain adjuster, which is what had started all this rebuild!

Installing the Valves

Once the rest of the parts arrived I rebuilt the cylinder head, installing the valves into their guides and really taking my time. Each valve goes into place, then I used the valve tool and paste to lap them into place and make sure the fit is tight with no burrs or visible holes. (Here is a YouTube film of a car engine being done). I could have saved myself this job if I'd recorded which valve came from where, but as I had to do it for the new valve, I did it for all of them to be sure. Check the servicing manual for the exact specs on all the parts to this.

|

| Wrong!! |

|

| Perfect fit! |

Installing the Cams

Mounting the cams is another one of those jobs, it's easy and can be quick, but make sure you get the timing set up correctly before you move on. In the service manual this part is done in two stages, 1. setting the timing, 2. installing the shims and setting the gap correctly. The service manual has a load of checks in it for all of these parts with the specs etc, it's a good idea to look at it.

Check the cams over for any wear and damage, for my bike, there is very little, but some things to look at specifically are chips of marks on the cam faces, damaged teeth, check the spring on the exhaust cam that releases the counter balance weight and the oil feeder on the intake cam. Also check the cam followers and the bars they sit on for wear. Install the intake cam first and work back to front.

|

| Intake cam on left, cam followers at top right. |

|

| Exhaust Cam, (timing out), Intake cam (Timing good) |

|

| Blurry pic, sorry! |

Once this is all built, then check the timing again and torque down the bridge for the final time. Pump the piston a few times and check the timing again, then pop the spark plug cover in place and mount the black engine casing with it's three bolts.

Remount the engine and reverse the initial process at the top of this post. When you're all done, say a little mantra, 'it will work, it will work' and hit the starter button. This will either make you smile or cry!!